Geo-services

Benthic

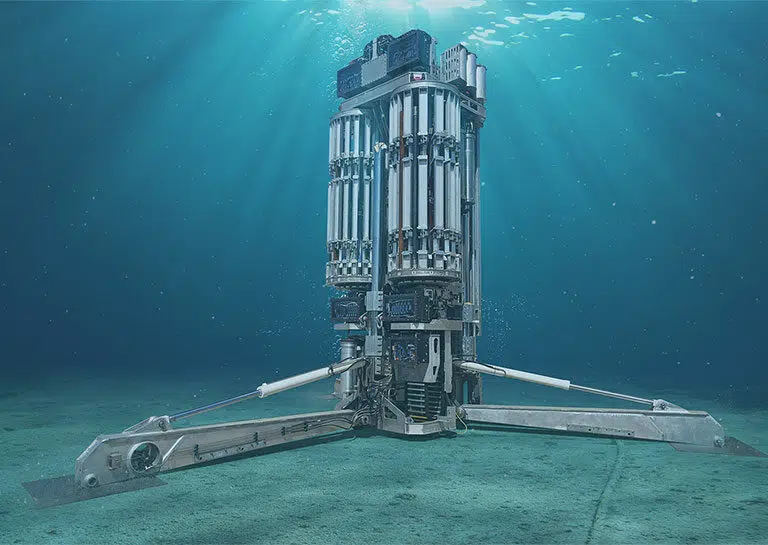

Smart geo-technical solutions built on safety and quality

Benthic is a service provider of geophysical and geotechnical consulting, engineering, design, and data acquisition services.

The company’s proprietary PROD technology has led the way in high quality, ultra-shallow and ultra-deep water site investigations, with capabilities in water depths up to 4,000m. Benthic’s innovative, proven technology and proven processes allow customers to obtain superior data quality to achieve their project objectives faster, safer and on budget.