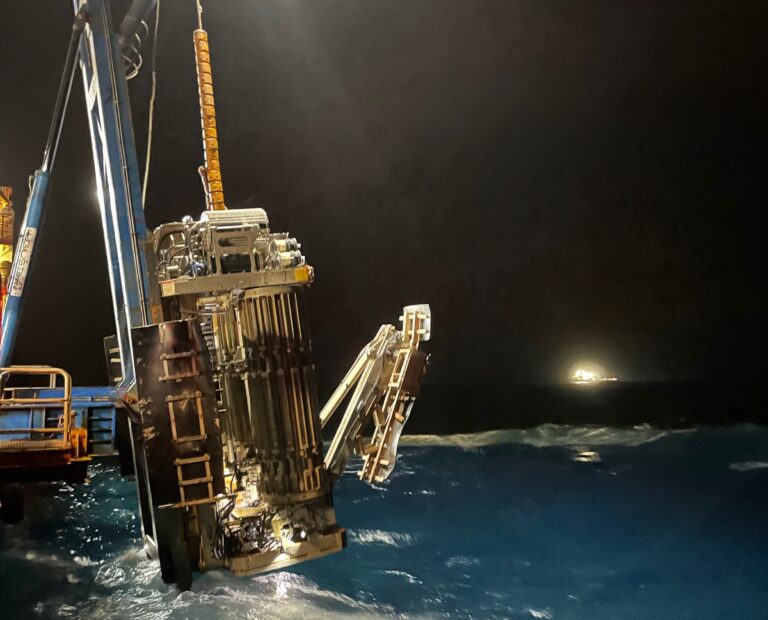

THE PORTABLE REMOTELY OPERATED DRILL (PROD) IS A FULLY SELF-CONTAINED, REMOTELY OPERATED SEABED DRILLING AND GEOTECHNICAL TESTING SYSTEM, CAPABLE OF OPERATING IN WATER DEPTHS UP TO 4000M AND INVESTIGATING SEABED DEPTHS UP TO 150M PENETRATION.

PROD has a proven, global track record including operations from shallow water to ultra-deepwater, challenging soil conditions and extreme seabed slopes up to 30 degrees, providing three to five times greater productivity when compared to a geotechnical drillship.

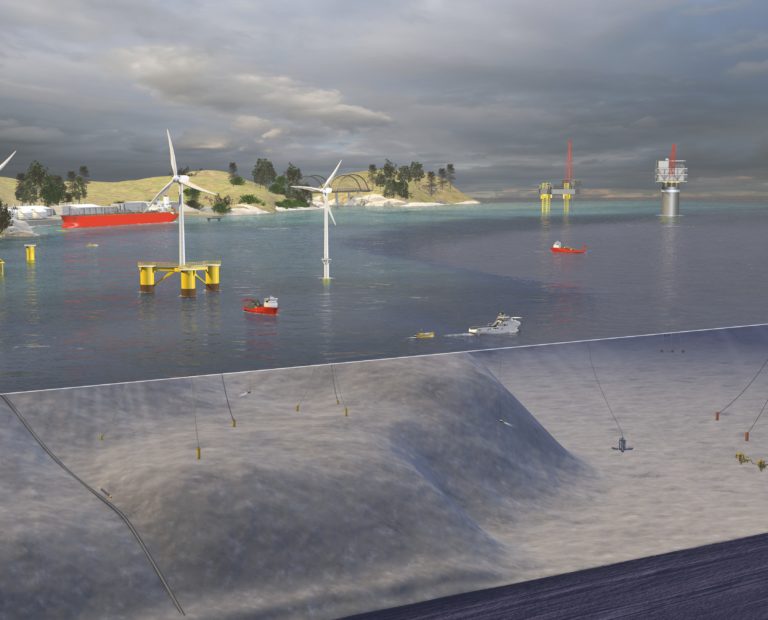

Using the high-quality data generated by PROD, Acteon’s team of experienced geotechnical engineers provide a complete solution, from site investigation planning, data gathering and sample testing, to data integration, interpretation, and foundation design.

Services include:

- Piezometer cone penetrometer testing

- Seismic CPT

- Thin kerf rotary coring

- Ball penetrometer testing

- Hydraulically tethered piston coring

- Hydrocarbon sensing

- Geological assessment

- Interpretive geotechnical reporting

- Post-project field reporting

Spec sheets and brochures:

Unmatched Efficiency in Deep Water Operations

Delivered by Benthic

Benthic is a global leader in offshore geophysical and geotechnical consulting, engineering, design and data acquisition services for the offshore renewables and oil and gas industries.

Integrate this product

Acteon can also offer an integrated project management service. This involves managing the activities of one or more of our companies on a customer’s behalf and providing a single point of contact for all aspects of project management.

GEO-SERVICES BROCHURE

Discover more about our solutions to real customer challenges and explore our full range of services to help you achieve project efficiencies.

Similar Products and Services

-

Acteon partners with accredited soil testing laboratories worldwide to conduct further...

-

Following offshore operations, Acteon can manage the sample transportation to an...

-

Working with in-house engineers and selected industry partners, Acteon offers a full...

-

Through the work of in-house engineers and selected industry partners, Acteon offers a...